PVC WPC Door Frame Extrusion Line

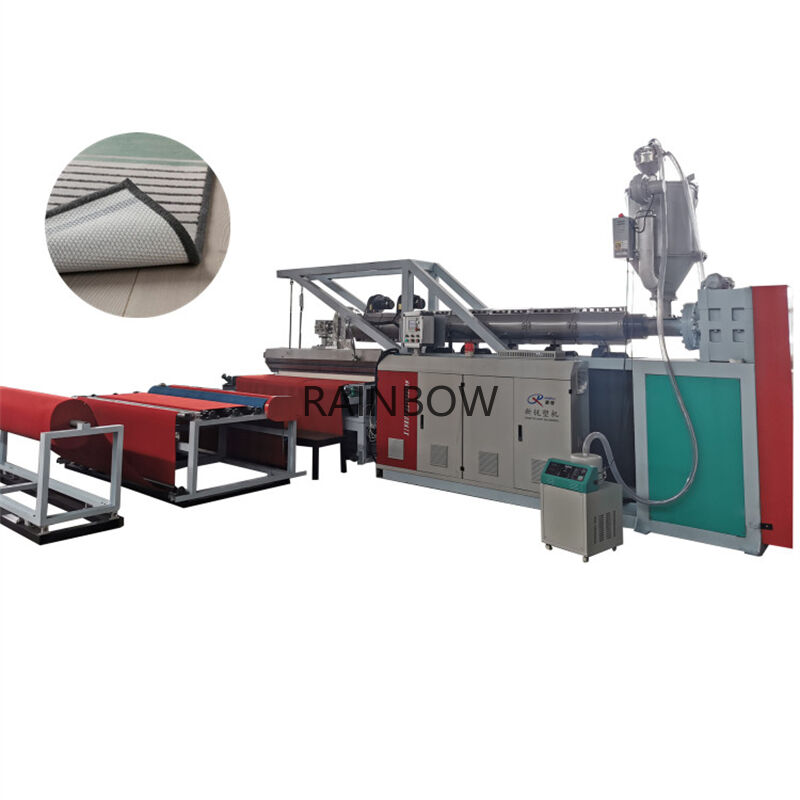

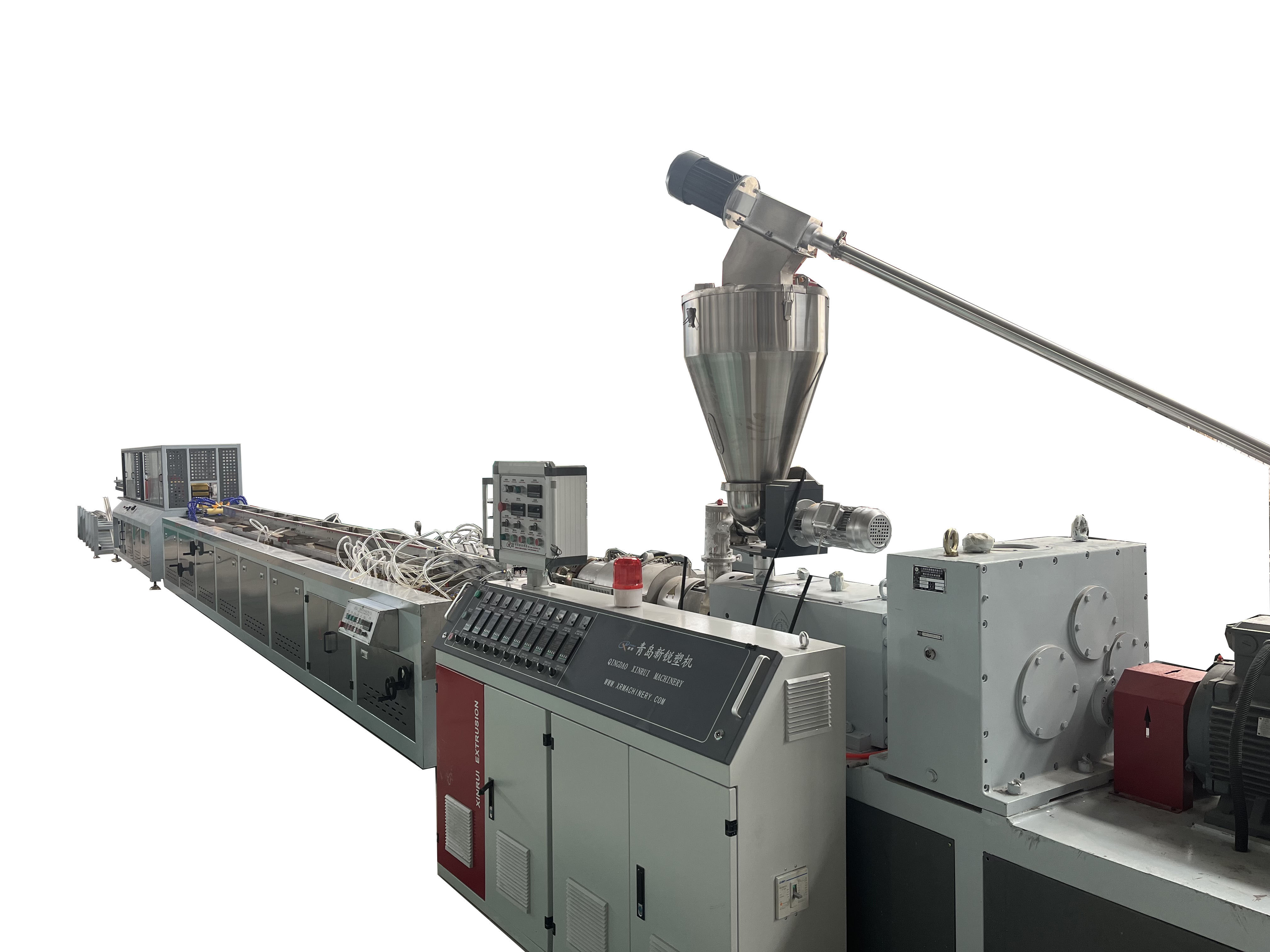

The PVC WPC Door Frame Production Line is composed of conical double-screw extruder, mold, vacuum calibration table, haul-off machine, cutter, and material reversal stacker, etc.

The extruder adopts AC frequency conversion drive system, and is simple to maintain. The main material is PVC and wood powder.

The PVC WPC door frame extrusion line is specially designed for producing door frames in various specifications and designs using composite materials such as PVC and wood powder. The complete production line includes a conical twin-screw extruder, mold, vacuum calibration table, haul-off machine, cutter, material reversal stacker, and more. It features a reasonable structure, high level of automation, easy operation, and convenient maintenance.

By simply changing the mold, customers can flexibly produce door frames of different sizes and styles to meet diverse market demands. We also offer personalized product design recommendations and mold development support based on the local market trends, helping customers expand their market presence and enhance product competitiveness.

The PVC WPC door frames produced by this line are waterproof, moisture-proof, insect-resistant, corrosion-resistant, easy to cut and nail, and environmentally friendly. They are widely used in home decoration, commercial spaces, schools, hospitals, and various other building environments.

PVC WPC Door Frame Machine: Mold

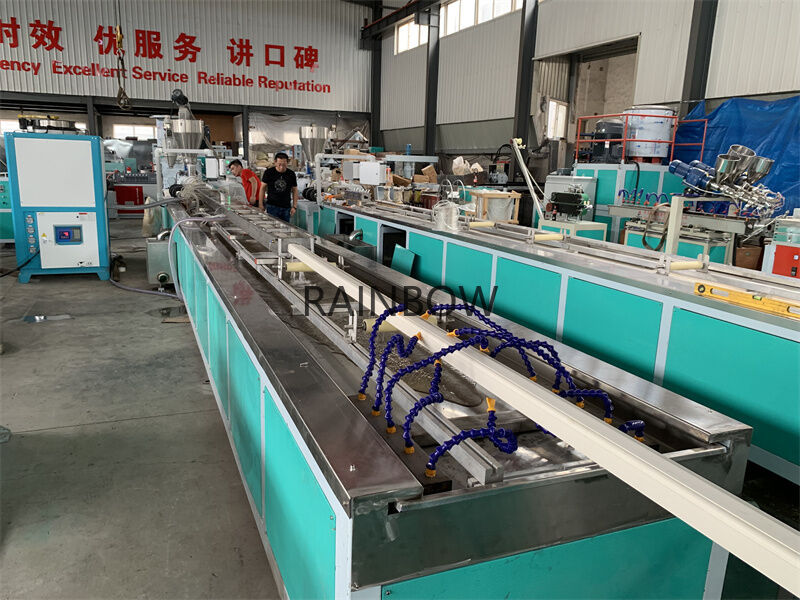

PVC WPC Door Frame Machine: 10M Water Tank

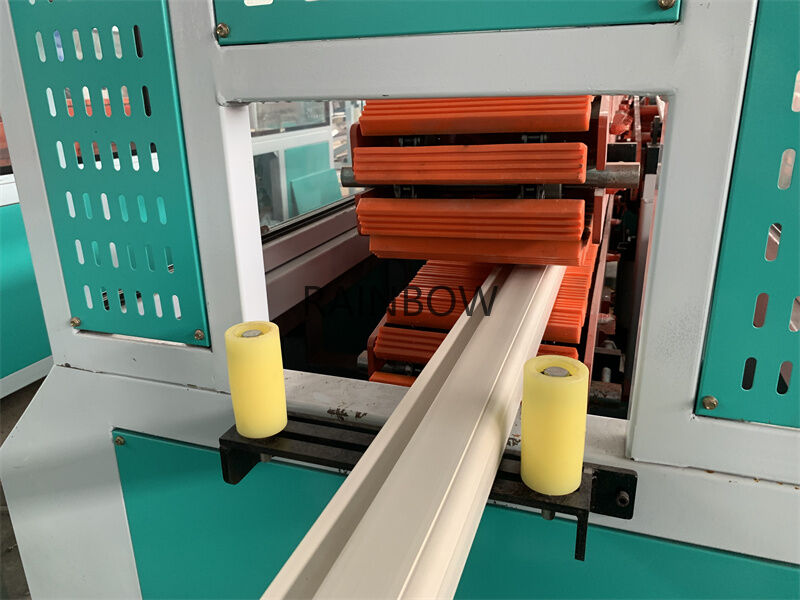

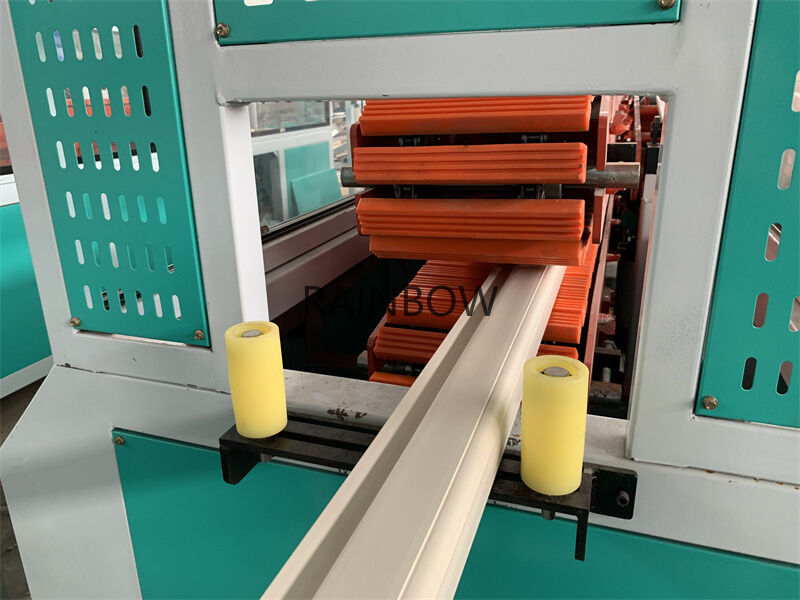

PVC WPC Door Frame Machine: Silicon Rubber Tractor

PVC WPC Door Frame Machine: Final Product

Features of WPC/PVC Profile Extrusion Machine

1.Reliable Temperature Control

Equipped with a dependable screw core circulation temperature control system, ensuring stable performance and consistent product quality when producing various types of profiles.

2.Adjustable Traction Pressure

The traction pressure can be freely adjusted to meet the demands of high-quality profile production. The powerful haul-off unit, combined with remote control for both traction force and speed, allows for easy and precise operation.

3.Precision Cutting System

The unique horizontal blade feeding design ensures clean and accurate incisions. High-performance alloy blades guarantee a smooth and high-quality cutting surface.

4.Synchronized Cutting & Dust Collection

The cutting system is synchronized with the extrusion process, ensuring smooth and continuous cutting. An efficient dust collection system helps maintain a clean working environment and supports environmental protection.

Request A Quote