Width:600-1200mm

Thickness:0.15-2mm

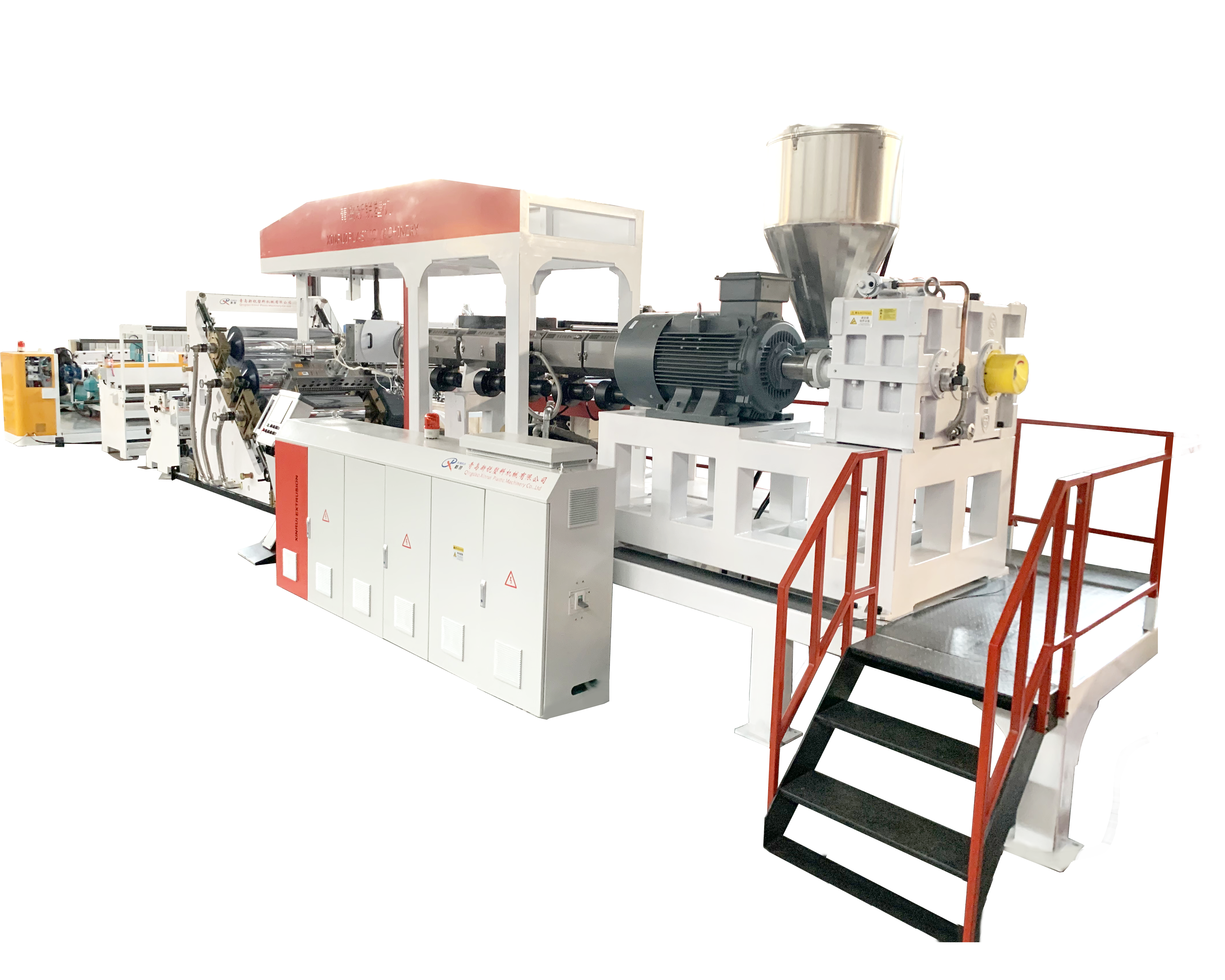

PP PE PS Sheet Making Machine

PP PE PS Sheet Size:

Width:600-1200mm

Thickness:0.15-2mm

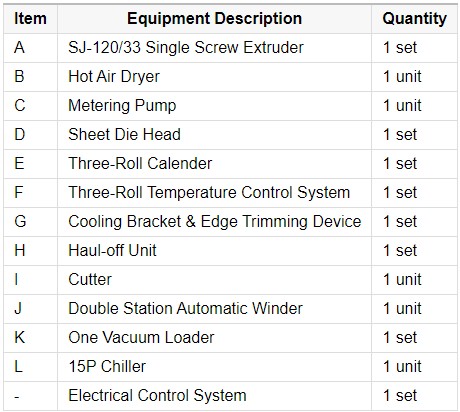

Machine Description:

(1)Gravimetric dosing system can realize proportionally precise mixing of several types of raw materials components.

(2)Hydraulic screen changer can effectively block the impurities from the raw material.

(3)Advanced Melt gearing pump is equipped to guarantee the raw material pressure more stable.

(4)T-die and online thickness scanner are equipped together to ensure the sheet thickness more uniformed and even.

(5) Three roller calendars can adopt horizontal type, oblique type, vertical type or other angles type designs to meet different types of sheets extrusion. The driving system of the roller calendars can be with common AC motor controlor servo motors control.

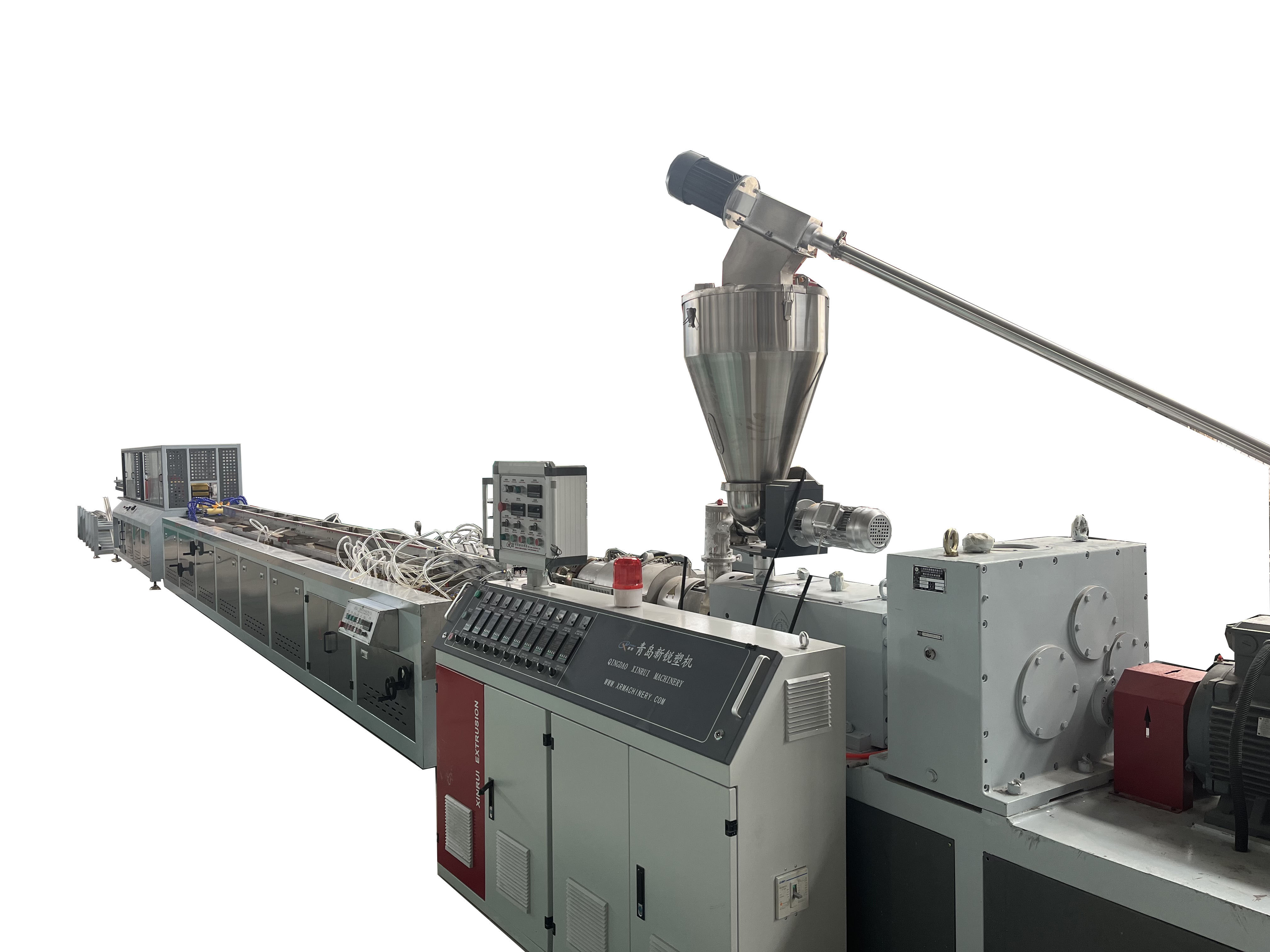

The PP co-extrusion sheet production line integrates multiple advanced technologies, encompassing key stages such as feeding, single-screw extrusion, die forming, three-roll calendaring, temperature control, cooling and shaping, edge trimming, haul-off, precision cutting, and product stacking. This forms a continuous and efficient production process, where raw materials are precisely proportioned and melted, then steadily extruded to ensure consistent operation and high product quality.

The extrusion system adopts a high-performance single-screw design, combined with precise temperature control and frequency conversion speed regulation, enhancing plasticizing uniformity and production capacity. The die features a dual-throttle adjustment design, enabling high-precision sheet thickness control to meet diverse customer demands for product thickness and performance.

The three-roll calendaring unit supports flexible angle adjustments (horizontal, vertical, and 45° inclined) and features a dual adjustment system (screw and pressure roller) for accurate control over the sheet forming process. An independent roll temperature control system ensures thickness uniformity and surface smoothness of the sheet. Equipped with a high-precision cutting unit and automatic length counter, the line guarantees precise sheet length and significantly improves production efficiency and automation.

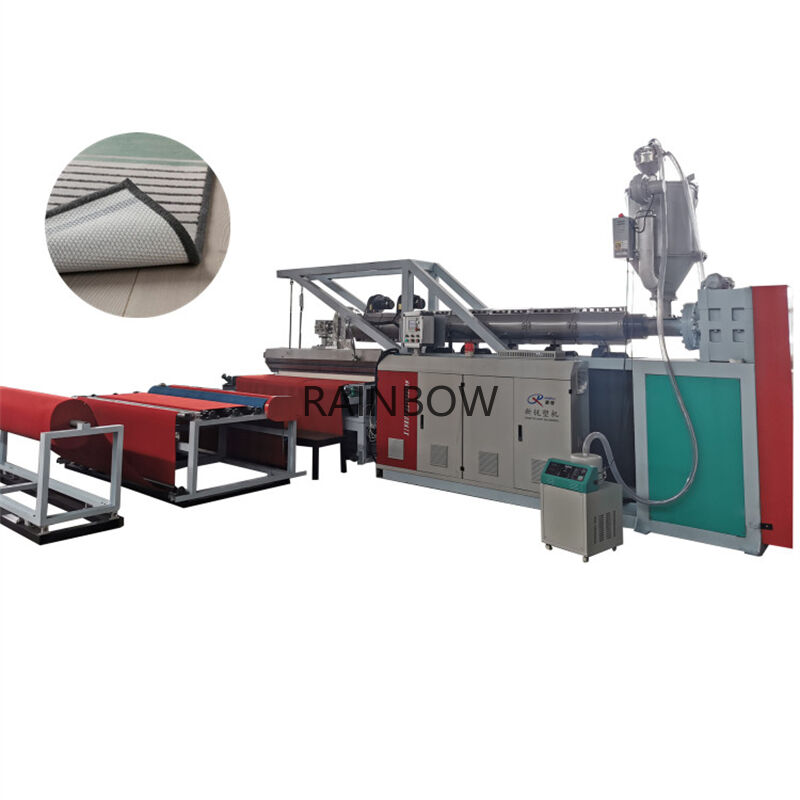

This production line is capable of manufacturing both multilayer and monolayer PP sheets, with optional embossing and coating functions that combine environmental friendliness with practicality. Additionally, it supports the production of PE, PS, ABS, and other types of sheets, realizing multi-material compatibility and offering a stable, reliable, and efficient intelligent manufacturing solution for a variety of industrial applications.

Application:

Due to excellent anti-oxygen and aniti-humidity feature,PP PE PS sheet is widely used in food containers, food packing,cups, tubs,bottles, buckets, DVD cases and such kind of thermoforming and packaging application.

Request A Quote