Width:600-1200mm

Thickness:0.15-1.5mm

PET Sheet Making Machine

PET Sheet Size:

Width:600-1200mm

Thickness:0.15-1.5mm

Product Description:

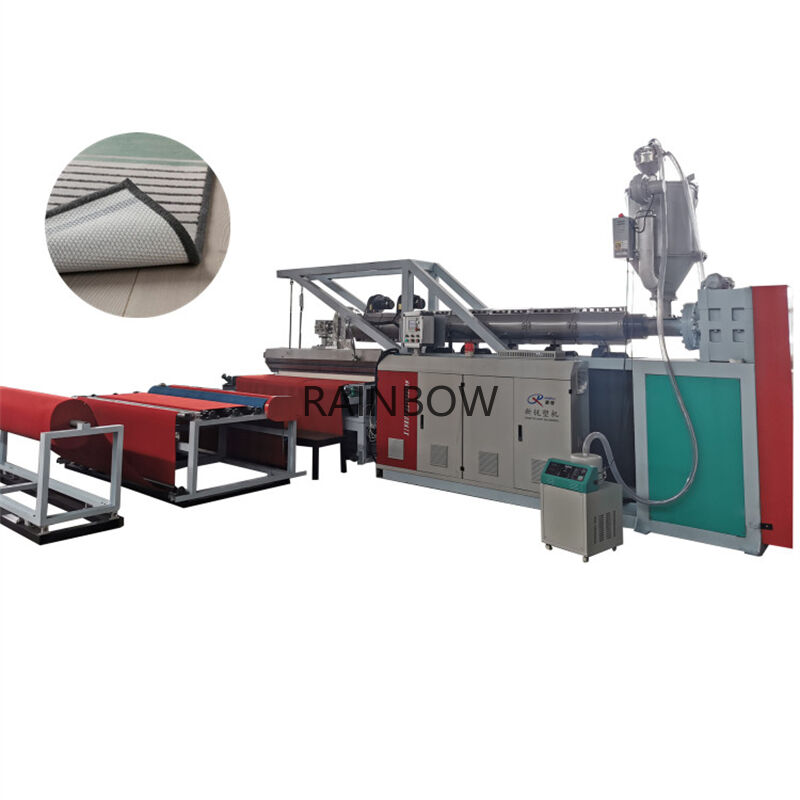

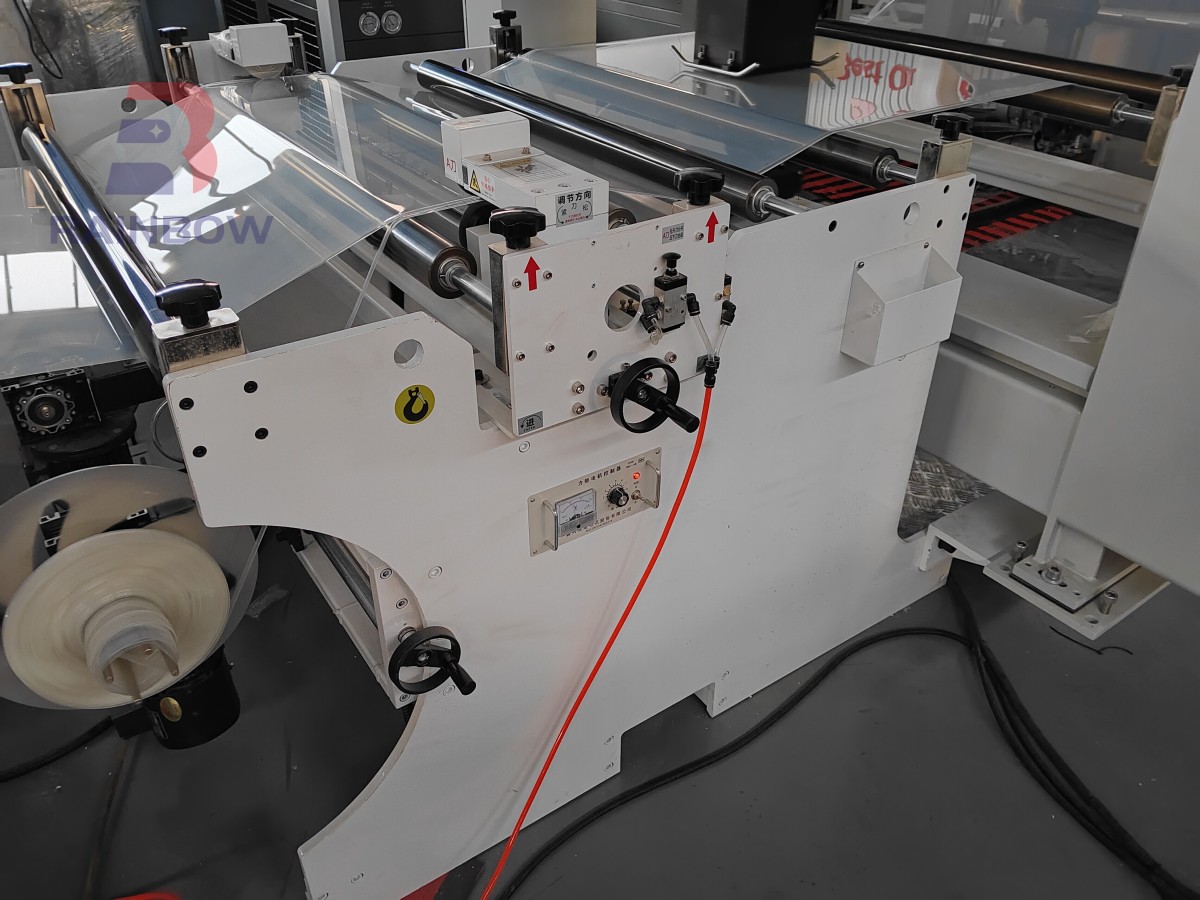

The manufacturing of PET (Polyethylene Terephthalate) sheets is a highly technical process that uses advanced machinery and complex compression polymerization methods. This material stands out from conventional semi-transparent plastics with its adjustable transparency, excellent ductility, and superior moldability, meeting a wide range of application needs. PET sheets offer exceptional resistance to common solvents and maintain stable performance across various conditions. Their superior thermal stability ensures they resist deformation and damage. With high clarity and a glossy finish, PET sheets enhance both the aesthetic and protective qualities of the final product. Being non-toxic and odorless, they comply with food safety standards, making them ideal for food, pharmaceutical, and medical packaging applications. Throughout the production process, precise control over intrinsic viscosity, moisture content, melt temperature, roller spacing, and temperature, as well as stretching and winding operations, is essential to ensure the uniformity, smoothness, and overall quality of the sheets. These rigorous controls ensure the outstanding performance of PET sheets in a variety of demanding applications.

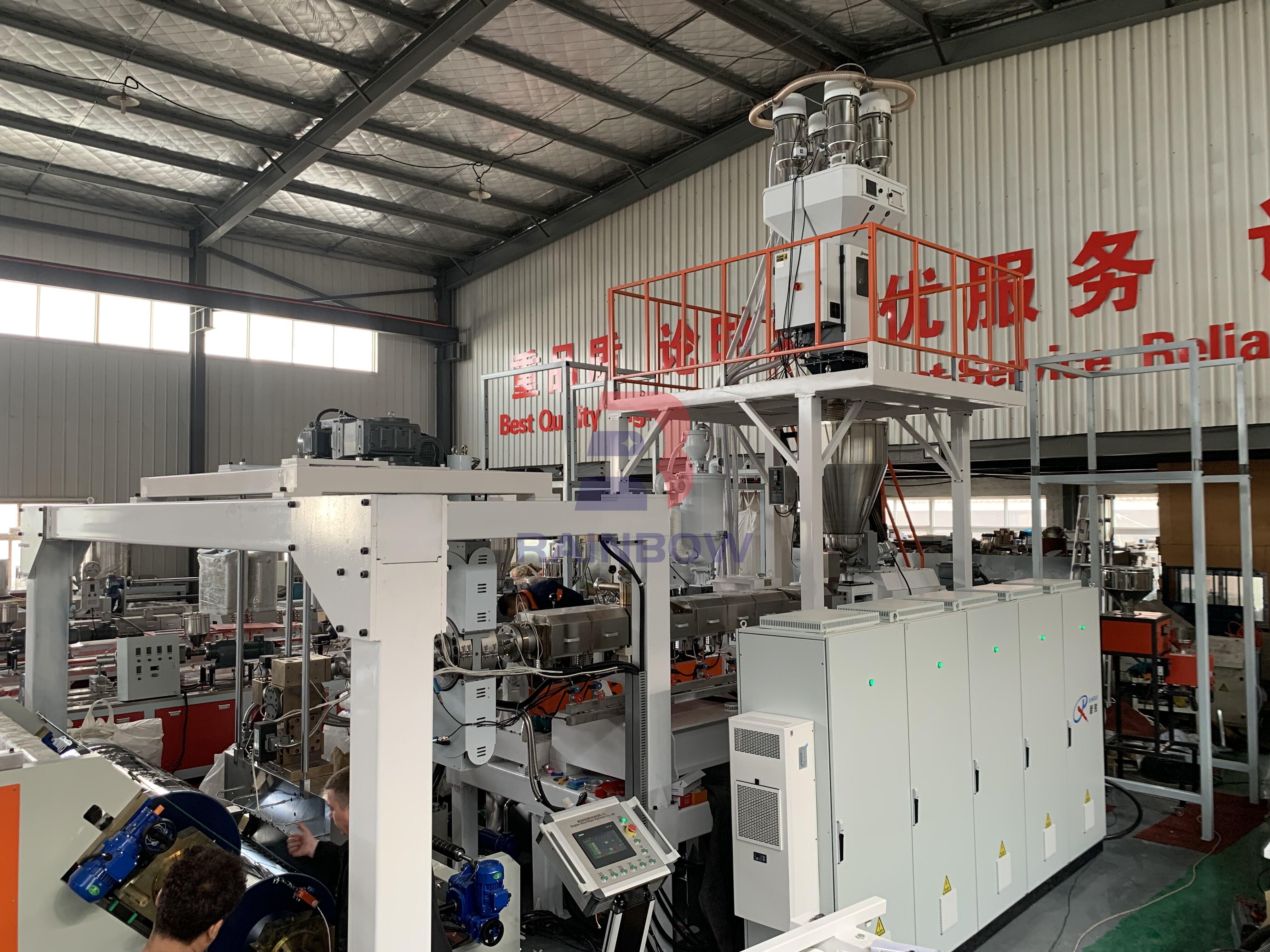

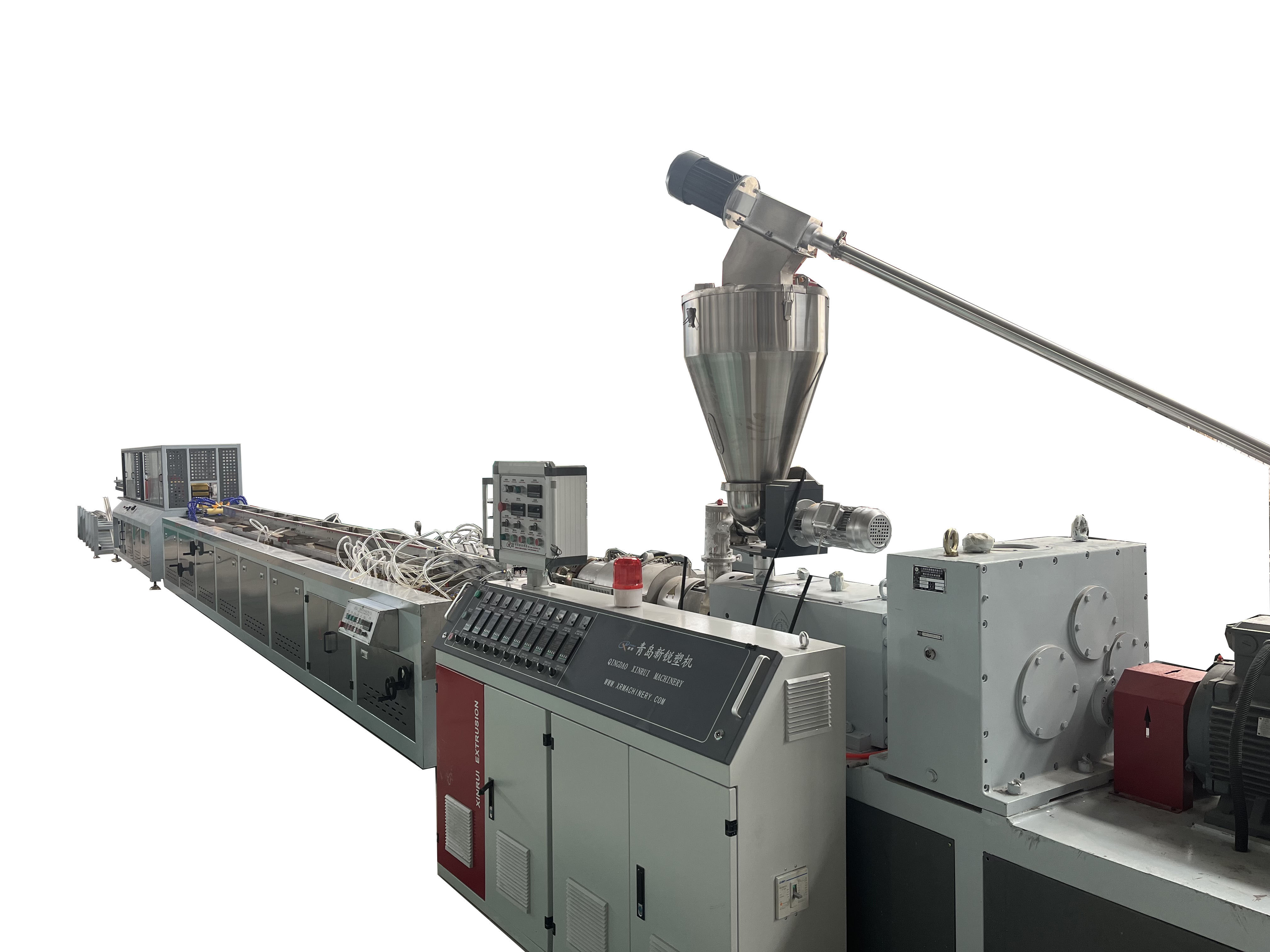

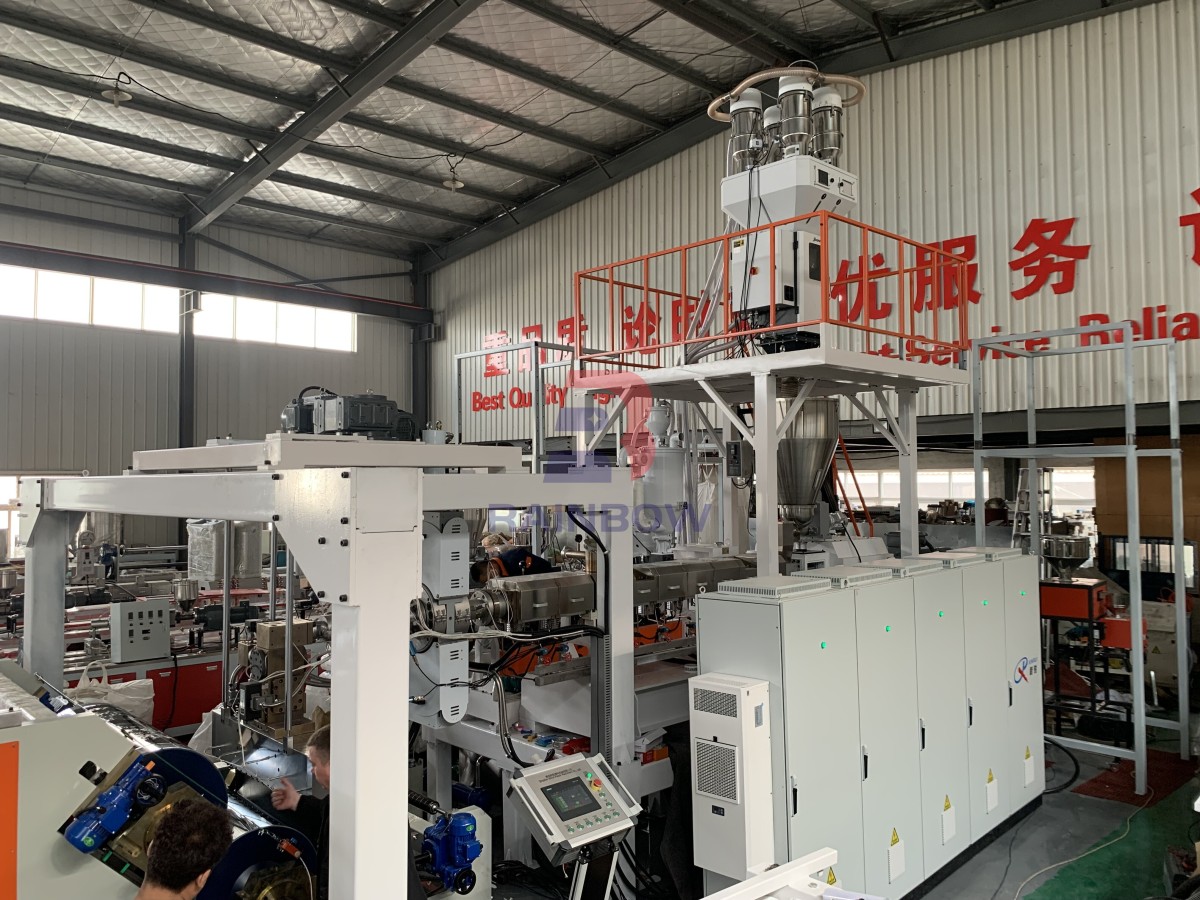

(1)The machine could adopt single screw extruder or parallel extruder according to the material situation and output capacity.This machine could process100% bottle flakes and virgin material.

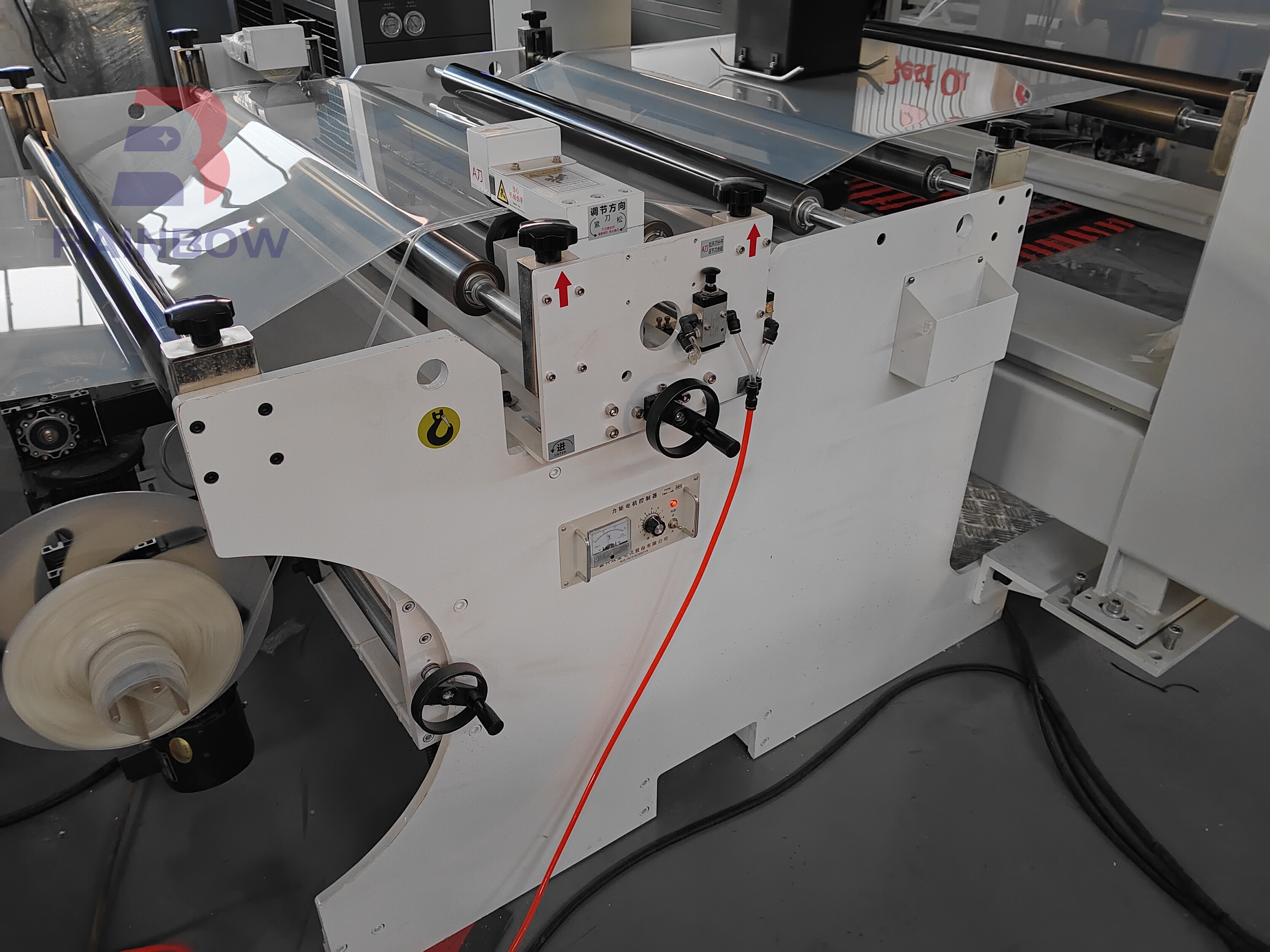

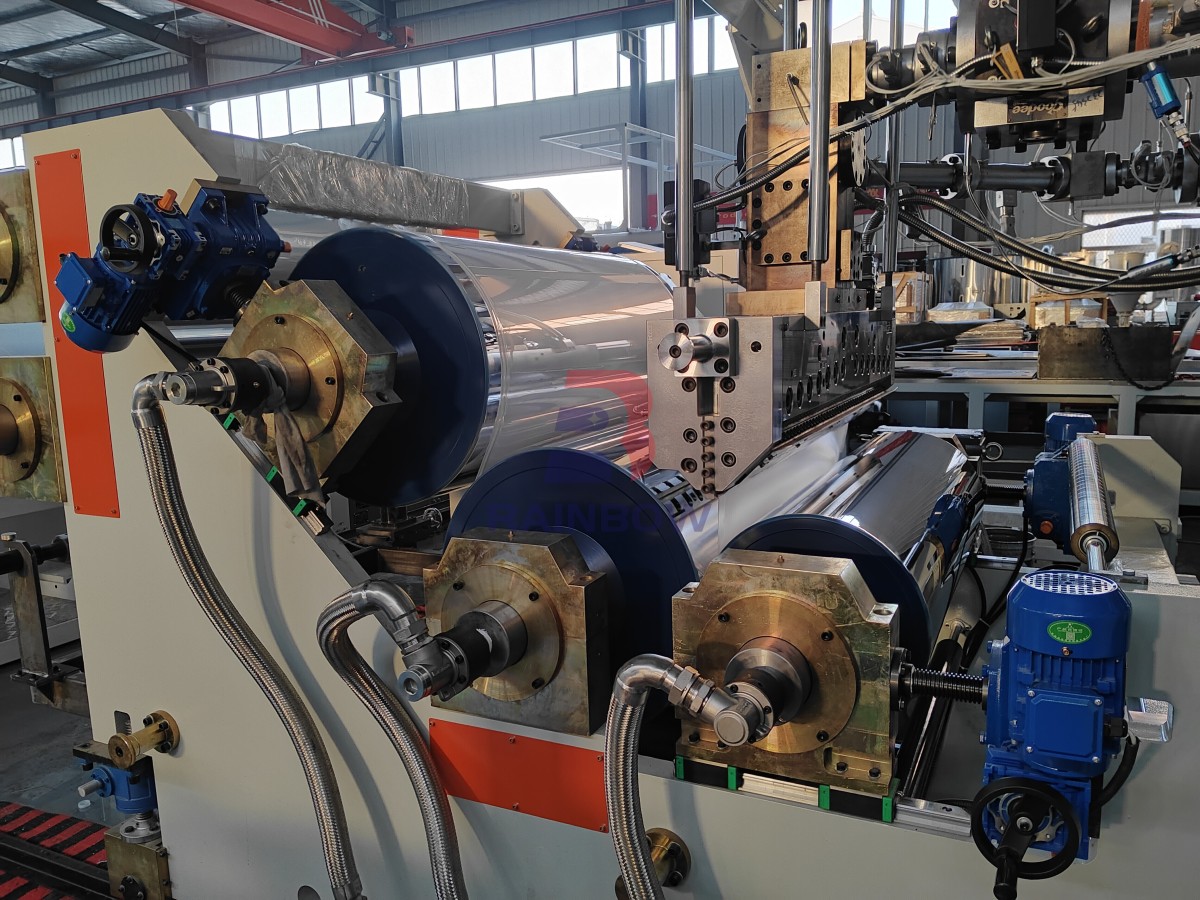

(2)T-die and online thickness scanner are equipped together to ensure the sheet thickness more uniformed and even.

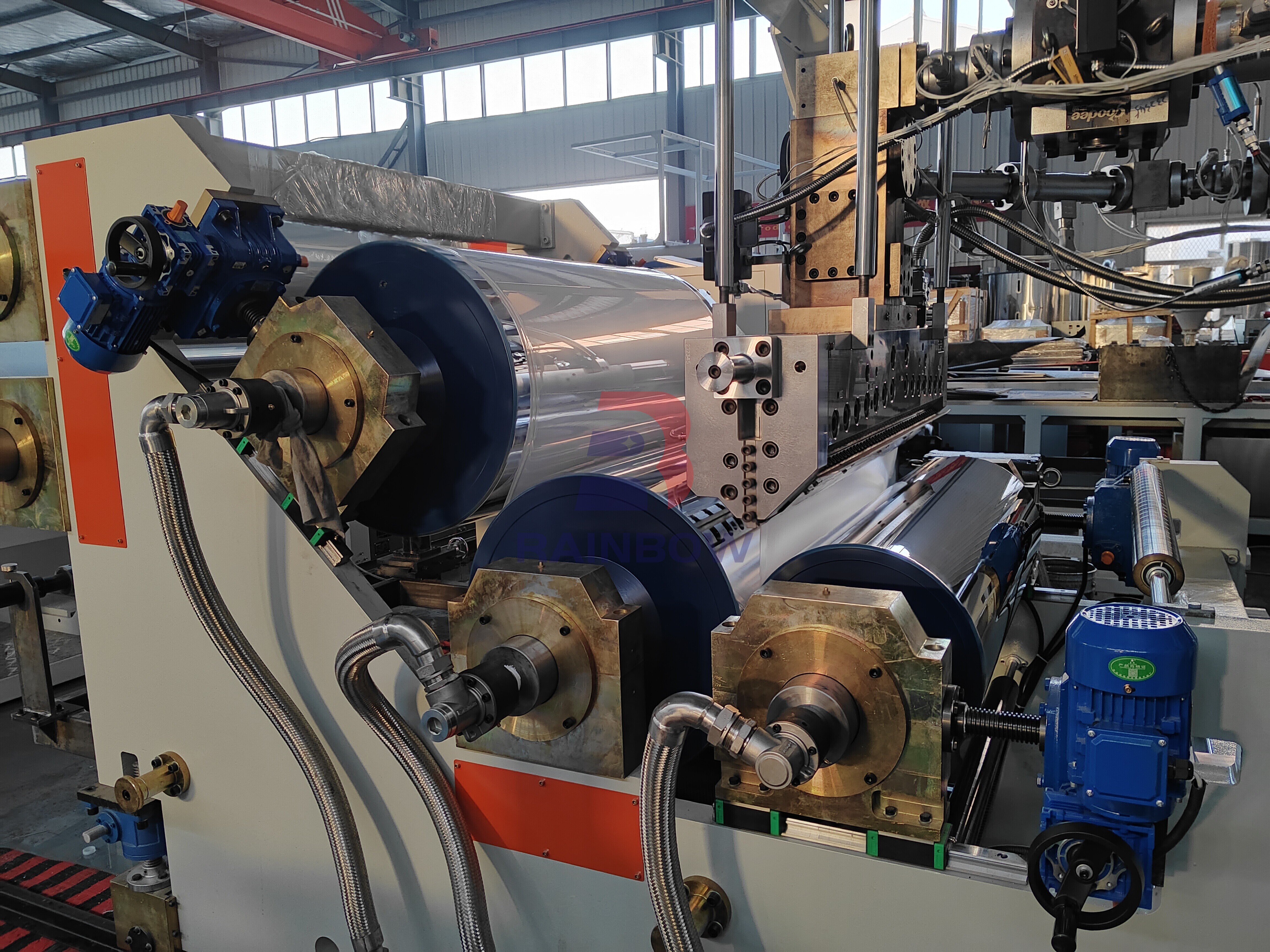

(3) Three roller calendars can adopt horizontal type, oblique type, vertical type or other angles type designs to meet different types of sheets extrusion. The driving system of the roller calendars can be with common AC motor control or servo motors control.

Application:

PETG is also called low temperature PET, and it is a new environment-friendly packing material with features such as high luster, good transparency,excellent property, self-adhesion, which is used for glue bonding and high frequency processing.PET stereoscopic optical sheets can be used as top grade package for cosmetics, medicine, tobacco and alcohol and common goods such as stationery, advertisements, posters and all kinds of cards etc.

Request A Quote